Want to learn how to sew leather at home? It's a lot easier than you might think and it can even be done on your sewing machine.

Just add the correct needle and presser foot for the job, and you'll be ready to get started! Practicing on a leather offcut before you start on the real thing is a must, as stitching holes are permanent on leather so you'll need to get it right first time.

Once you feel confident, try a small project like this stylish passport wallet. In this tutorial, we will take you through the tools you'll need and how to master the technique for a neat finish, and show you how to make a topstitched leather passport wallet to take with you on your next adventure.

Stitching with leather is simple to do – you'll just need to take your time, as there’s no room for mistakes because the stitches create a permanent hole in the leather. Leather can be stitched by hand, which requires a few tools and special thread and needles, but it can also be sewn with an ordinary sewing machine. You just need a little practice and a few tips to get you started.

This tutorial first featured in Simply Sewing Magazine. Simply Sewing is the UK's best-selling magazine for makers who sew will have you at your machine from the get-go! Each issue includes fresh projects for your home & wardrobe, beautiful photos and step-by-step guides.

New to sewing? We've got lots of great beginner's guides to help you get started. Check out our sewing for beginners and how to use a sewing machine guides to learn the basics. Stock up on some craft supplies with our best sewing machines for beginners and sewing kits for beginners.

Read on to learn how to sew leather with our easy tutorial…

How to sew a passport wallet

You will need

Leather

Leather, suede and nubuck are all sewn and worked with in the same way. Leather can be very stiff or more pliable and flexible, depending on its thickness. When you buy leather, its thickness is described in ounces or millimeters, so the lower the number, the thinner it is. You can find conversion charts online if you want to find out how thick in mm each ounce of leather is.

The leather that is generally used in garment making is 2oz, which is just over 1mm thick. You can stitch with a leather thinner than this or slightly thicker, but 2-3 oz is just about right for home sewing using domestic machines.

Sewing machine foot

Leather has a tendency to stick to the machine plate or foot, so it’s best to fit your machine with a Teflon foot, roller foot or walking foot to help ease it through as you're stitching. These can be bought from sewing machine shops or easily online.

Needle

Use a specialist leather sewing machine needle as it will make sewing much easier and give you better results. These needles have a strong shaft and a wedge-shaped cutting point so are specifically designed to cut through the leather and will withstand the extra thickness. A size 90-110 (14-18) needle is best for stitching with the slightly thicker thread you’ll need. It's advisable to always use a new needle when you start a project so it’s nice and sharp.

Thread

Use a pure nylon or polyester upholstery weight thread; a 40 weight thread is ideal. Synthetic threads are stronger and more durable than cotton, so are better for stitching on leather.

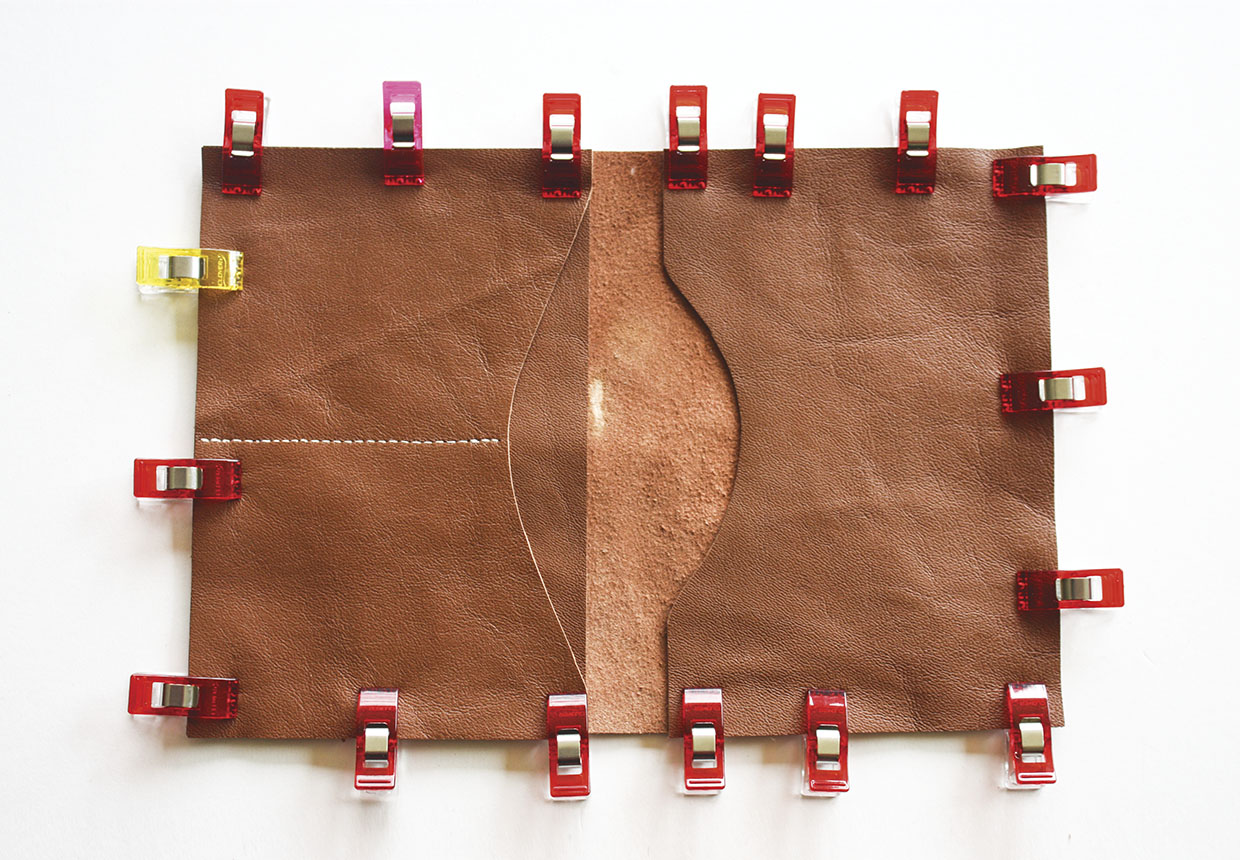

Fabric clips

Pins will leave permanent holes in leathers, so fabric clips are best to use to hold pieces together whilst stitching. These can be bought in packs in a variety of colours, or you can use small bull dog clips instead.

Working with leather

Cutting

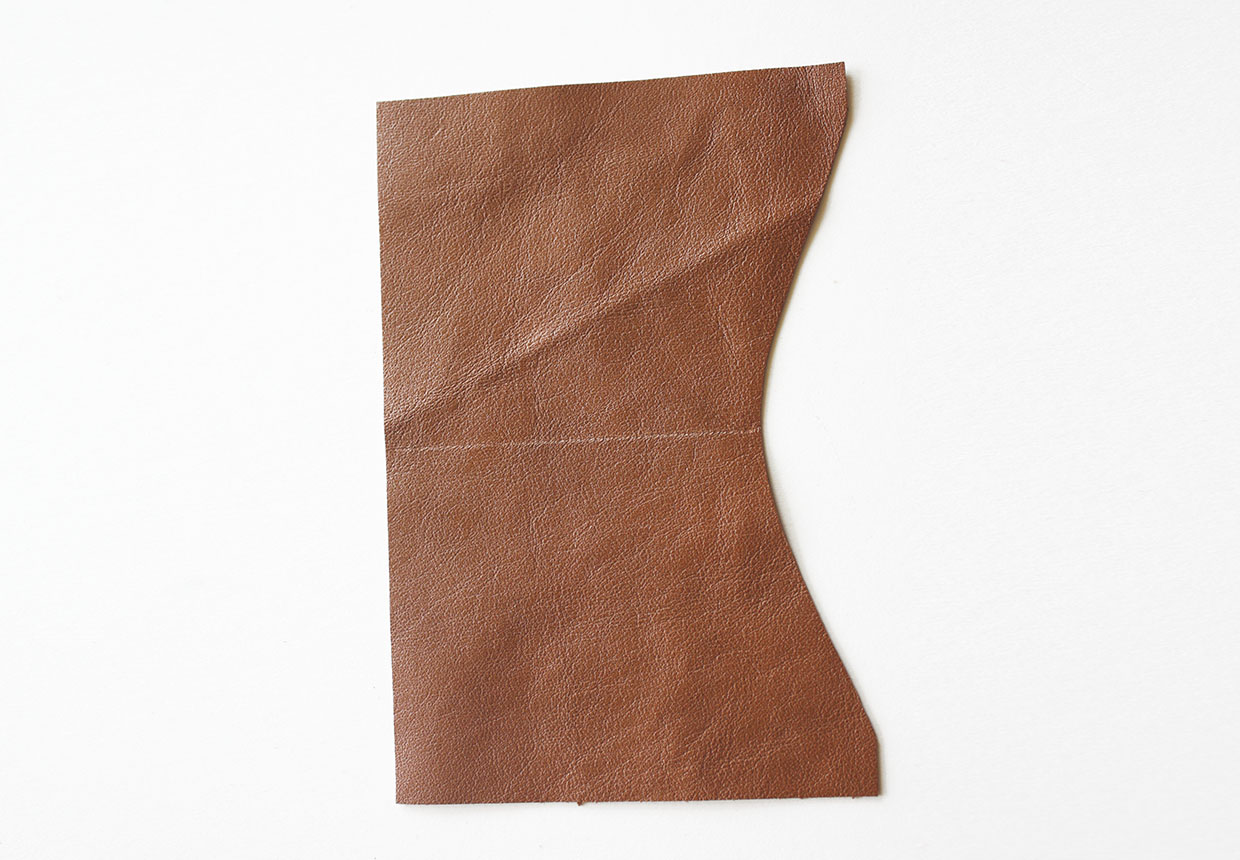

Only cut a single layer at a time as leather moves and stretches whilst cutting. If you have pieces which need to be cut on the fold, draw around one part, flip it over and draw around the other for a more accurate cut. As you can’t pin the pattern to the leather, weight it down on the wrong side and draw around it in pen or chalk then cut along the lines. You can use a rotary cutter for cutting straight lines, but for curves, dressmaking scissors will be fine.

Clipping

Clip the leather pieces together before you sew, or use leather tape to stick the leather together within the seam allowance.

Stitching

Before you start, remember that every stitch leaves a permanent hole, so do all your testing and fitting beforehand. Always, always work a test piece first to make sure you’ve got your stitch length and tension correct. Use a longer stitch length of about 3-3.5 to create a strong and secure seam. Stitch slowly as this will help with accuracy and also to ease the leather through your machine. If your leather gets stuck in the machine, lift the foot and allow the leather to relax for a moment before continuing.

Working seams

As the raw edges of the leather won’t fray, you don’t need to finish any edges. There are several different sorts of seams you can use: lapped seams, faux flat-fell seams, single or double topstitched or just plain seams – it just depends on the finish you want. You can even glue seams using special leather adhesive if you prefer. Once you’ve finished a seam you can open it out flat and topstitch the seam allowances down either side of the seam. Trim the seam allowances down close to the topstitching to reduce bulk.

Finishing seams

You can’t iron leather as the heat can damage its surface, so, instead, open the seam out and press it flat using a rubber hammer or a small roller.