Cyanotype printing is a fun and experimental craft which can be used on a wide range of surfaces and mediums. This solar photography technique is most commonly used on thick paper and fabric, but the method is the same for both mediums.

It’s a great craft to try incorporating into your sewing projects, allowing you to make your own unique and custom fabrics.

You can try making lots of small sections of cyanotype fabric to use in patchwork projects, or alternatively you could make a larger fabric print and then cut out your favourite parts.

What material should be used for cyanotype printing?

When creating cyanotype fabric it’s best to use natural untreated materials such as an undyed 100% cotton, linen or hemp.

We’ve used calico cotton in the following tutorial, but it’s worth noting that the thickness of the fabric will determine how much of your print shows through on the other side.

If you were to use a thin fabric such as silk, then you can potentially make a double sided cyanotype fabric as the material will be thin enough to see the print on both sides.

Get your cyanotype printing materials

Want to try it yourself? Find all the materials you need to make cyanotype fabric here.

Is cyanotype printing safe?

As long as you use common sense, follow instructions and take basic precautions, cyanotype printing is perfectly safe.

Cyanotype printing occurs due to a chemical reaction that takes place when exposed to the UV rays of the sun. These chemicals are of a very low toxicity so are safe to work with.

The cyanotype solution can easily stain both skin and fabrics, so you should wear rubber gloves and protect surfaces with newspaper when handling the solution.

While it’s a very minimal risk, there’s the potential for a very small amount of fumes to be created when making your prints (especially if you are experimenting with adding in different ingredients), so working in a well ventilated area and wearing a face mask is also advised.

When making cyanotype fabric, remember that your solution may soak through the material, so ensure there is adequate protection underneath your fabric.

The chemicals involved can be an irritant. If you get any solution on your skin wash immediately. If you accidentally get any of the solution or dry chemicals in your eye, wash with cold water and seek medical advice.

You can find more safety advice in our full guide to cyanotype printing.

How to care for your cyanotype fabric

Once you’ve made your cyanotype fabric, it’s advisable to keep washing to a minimum. To preserve your prints it’s best to hand wash in cold water using a non-phosphate detergent.

Most of the big name laundry detergents are phosphate free but you should always check first.

How is cyanotype fabric made

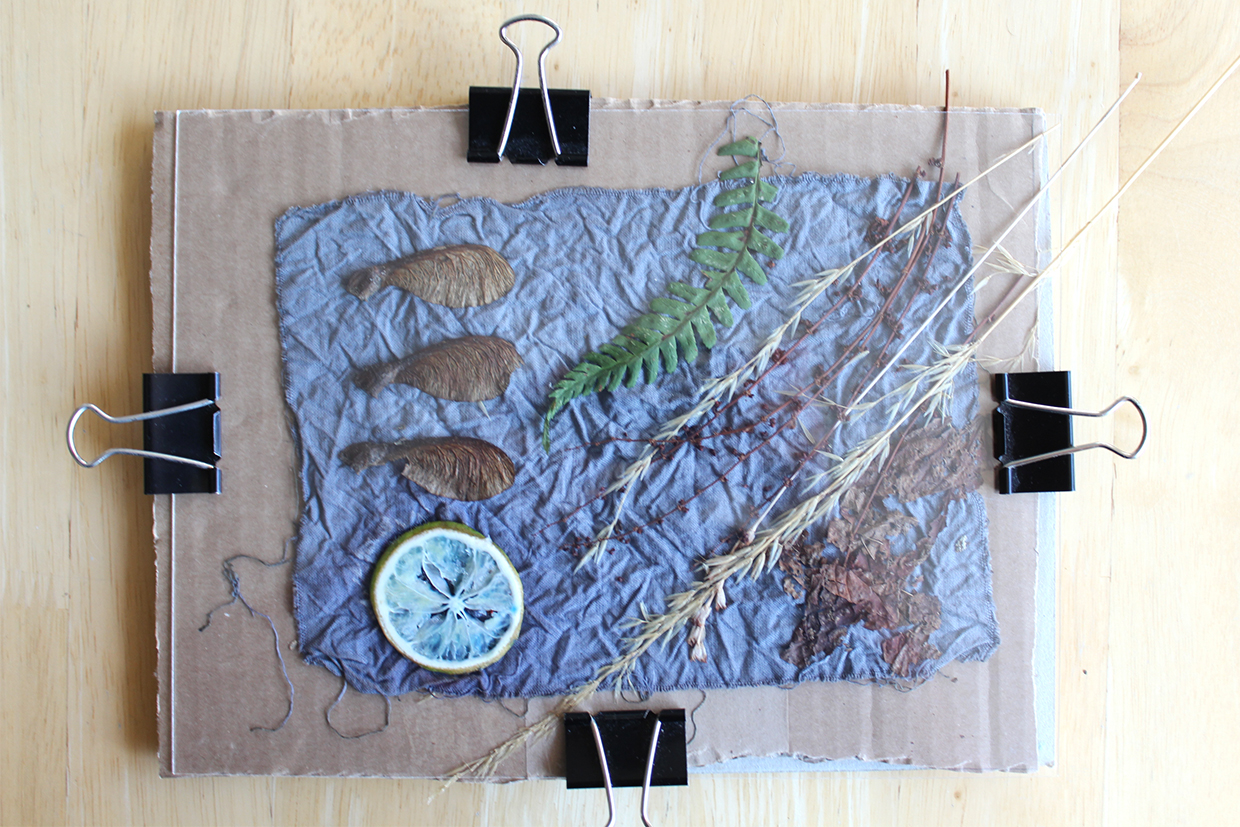

Cyanotype photography works by coating a fabric surface in a light-sensitive solution. You can buy pre prepared fabric or you can mix and apply the solution yourself.

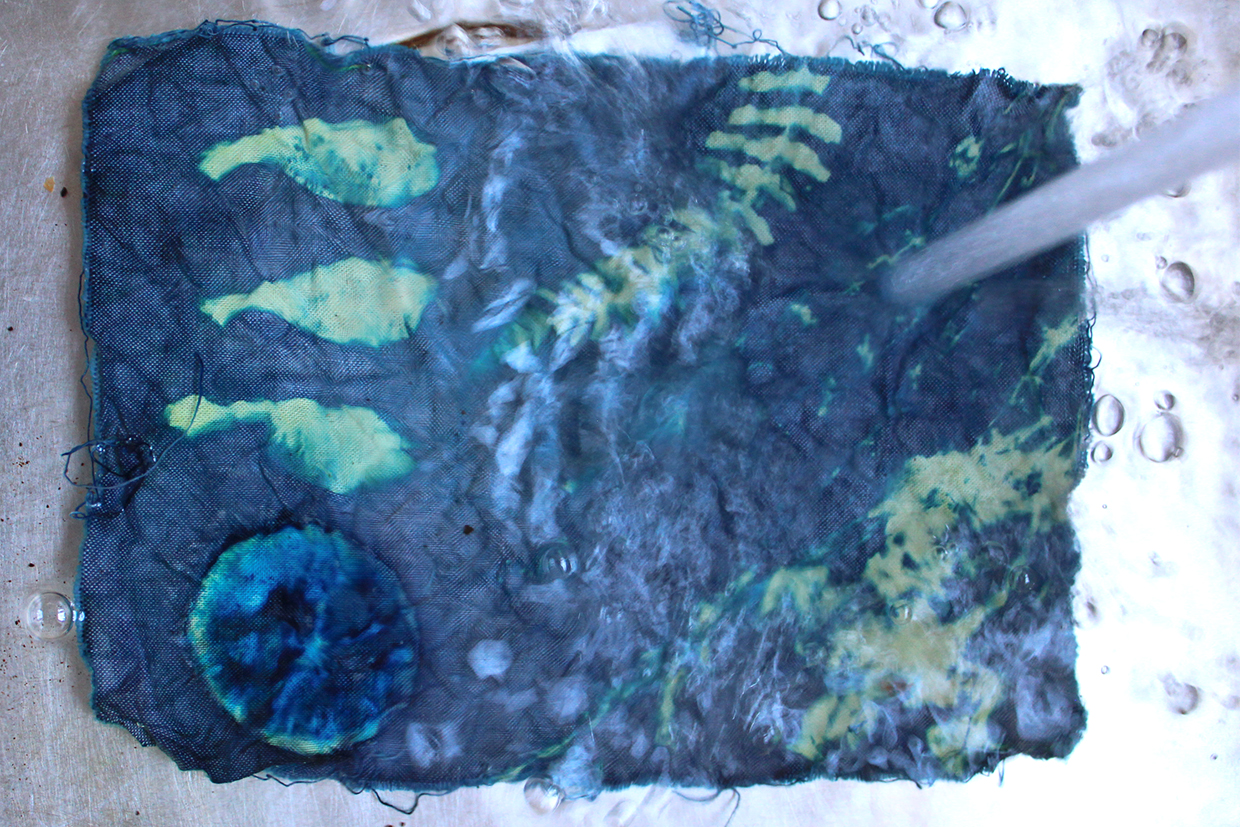

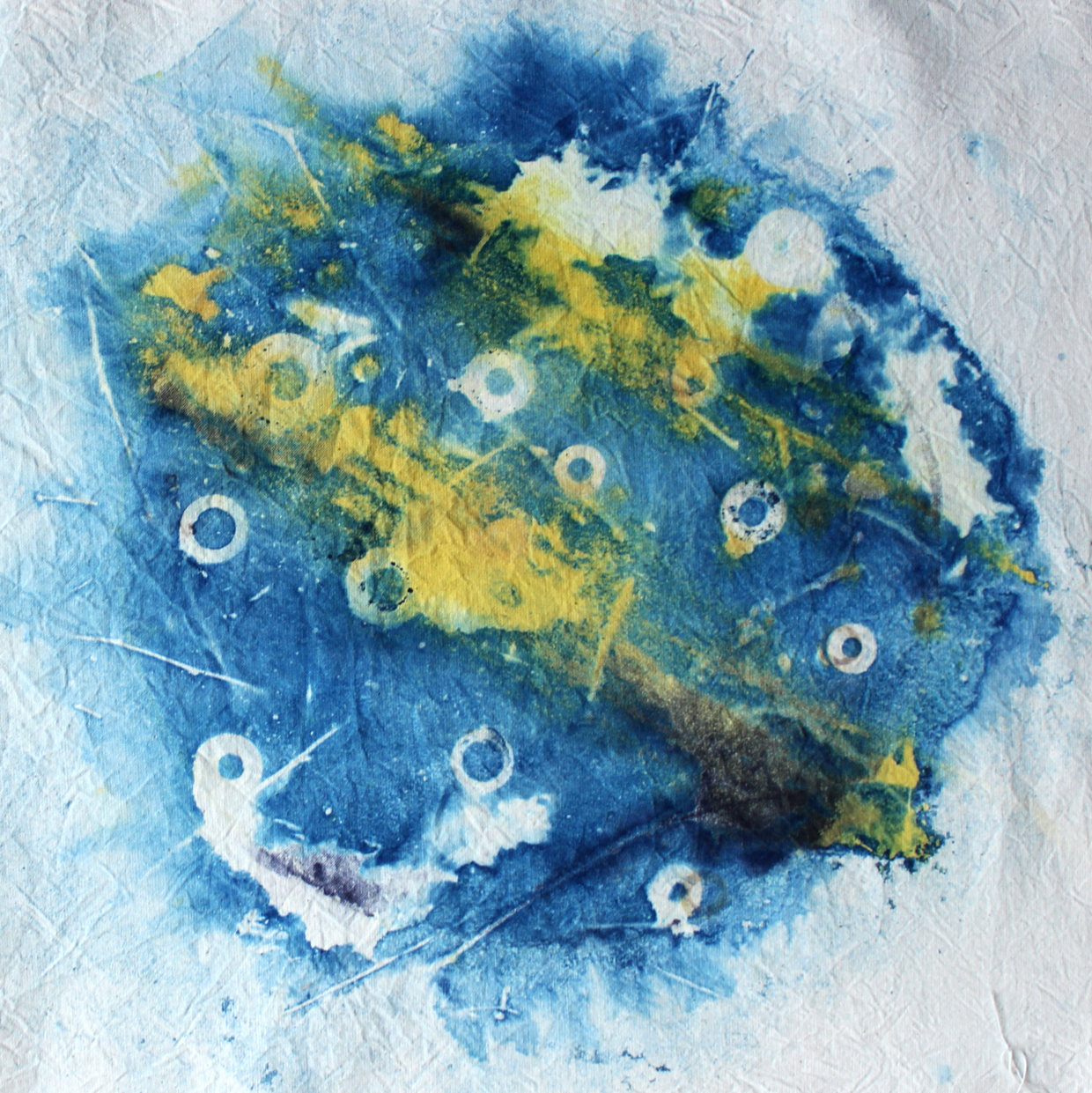

Objects are then placed onto the surface before being exposed to the sun. The areas that are exposed to the sun react with the UV rays, whereas the areas that are covered by your objects do not - creating a negative silhouette style image.

When your fabric has been adequately exposed you then wash the solution off the material, where you will see the classic cyanotype Prussian blue develop.

You can find a full explanation of the scientific process as well as loads more handy information in our guide to cyanotype printing.