Cold process is one of the most popular soap making techniques and it’s easy to see why: it’s versatile, simple to customise and good for your skin!

If you’ve already had a go at melt and pour soap making, moving on to cold process soap making is the natural next step. It requires a little more technical knowledge than melt and pour, but it’s well worth making the effort to learn.

You’ll love experimenting with different scents and colours to make your own beautiful soaps. Use your soaps at home or share them with friends and family as wonderful handmade gifts.

In this guide, we’ll look at the cold process soap method, the benefits of cold process soap, what you’ll need to get started and a recipe for you to try at home.

What is cold process soap?

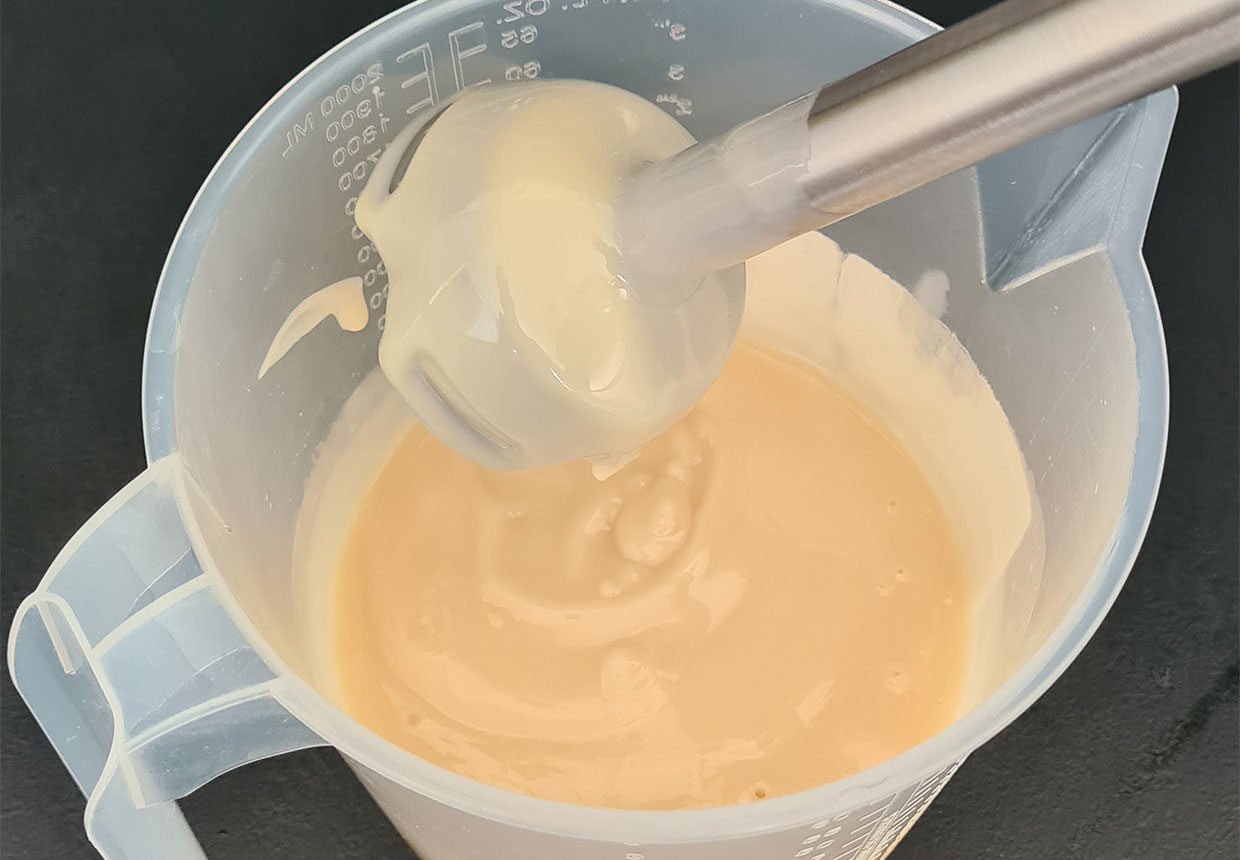

The cold process soap making technique involves combining oils with lye (sodium hydroxide). This triggers a chemical reaction called saponification, which transforms the mixture into soap.

Saponification is an exothermic reaction, meaning that heat is generated as part of the process. However, there is no need to heat up the soap mixture yourself as you would with hot process soap making.

If you’ve already tried melt and pour soap making, you’ll find this process a little different. When you make melt and pour soap, the base is ready-made and has already been through the saponification stage.

Cold process soap is a little more difficult because you’ll need to oversee the saponification process, but the upside is that you get much more control over the recipe and how it turns out.

Due to the chemicals involved and the heat created by the exothermic reaction, you’ll need to take safety precautions when working with cold process soap.

Lye also releases toxic fumes and can irritate the skin, so wear protective clothing including gloves and goggles during the soap making process and make sure the room is well-ventilated.

Cold process soap benefits

Cold process soap has plenty of fantastic benefits! For starters, it’s kinder to your skin. The saponification process produces glycerin, which makes the soap more moisturising.

You can bring skin-friendly ingredients into your cold process soap recipe too, such as olive oil and coconut oil. It’s also possible to add goat’s milk to your recipe, which is said to soothe dry and irritated skin.

Cold process soap can also be customised with essential oils and fragrances, such as lavender oil or rosemary oil. Choosing the right fragrance can transform your soap making!

Feeling creative? There are lots of ways to make your cold process soap look stunning, from building up colourful layers to creating incredible marbled effects. For a professional finish, shape the top of your soaps or add a sprinkling of dried flowers.

Frequently asked questions about cold process soap making

Ready to begin? We’ve answered some common cold process soap making questions to help you get started.

How long does cold process soap need to cure?

Cold process soaps need around 4-6 weeks to cure before they are ready to use, unlike melt and pour soaps which can be used after 24 hours.

How long does cold process soap last?

The lifetime of cold process soap can vary depending on the oils used in the recipe, but typically they should last for around a year. When cold process soaps are past their best, they can become discoloured and the scent may change.

When to cut cold process soap

There’s no set timeframe for when cold process soap is ready to cut. As long as it is firm enough it can be ready to cut within a few hours, but some soaps may require a few days to harden.

When to unmould cold process soap

You should unmould your cold process soap when it has fully set. It may take several hours or days to be hard enough to unmould.

How to make cold process soap without lye

Unfortunately it’s not possible to make cold process soap without lye, as it’s necessary to transform the fats into soap. If you’re nervous about handling lye, you can stick to melt and pour soap making as the base has already been through saponification.

How much essential oil to add to cold process soap

It’s recommended to keep the amount of essential oils under 3% of your soap recipe, in keeping with EU recommendations. If you use too much essential oil in your soap, it may irritate the skin.

Which is the best oil for cold process soap?

Palm oil works well in cold process soap because it adds hardness to the finished bar and creates a conditioning and creamy lather. However, palm oil is also associated with deforestation and environmental damage.

In our cold process soap recipe below, we’ve used babassu oil in its place. This has a similar effect in soap, although the lather is more bubbly than creamy.

Coconut oil is another soap making favourite. It adds hardness to the bar, and cleansing power. It usually needs to be paired with other oils though, because it can be drying if you use too much in the recipe.

Olive oil is another brilliant oil to use in cold process soap. It creates a conditioning lather and balances out the cleansing power of coconut oil. Castor oil is great for adding extra bubbly and creamy lather to your soap, but it is best used in small quantities.

Should I refrigerate cold process soap?

Sometimes the heat produced during the saponification process can alter the colour of the soap or cause it to crack on the surface. This is called the gel phase.

To prevent this from happening, you can put your soap into a fridge for the first 24 hours of the process.

Cold process soap making supplies

Ready to try making cold process soap for the first time? We’ve created a straightforward recipe for you to make. Before you begin, here are some essential materials to buy…

Oils

Oils are an important part of the cold process method, as they will have an impact on the consistency and texture of your soap – including how well it lathers.

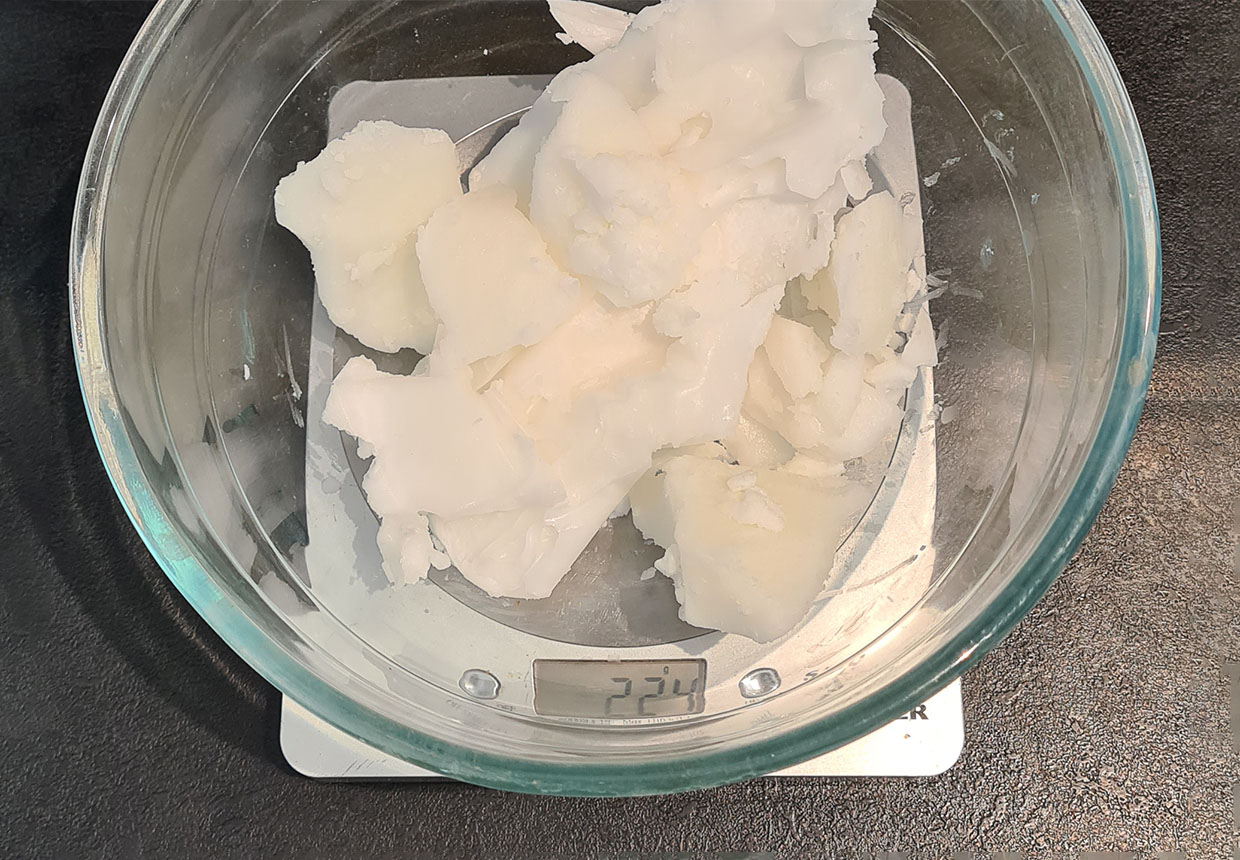

Coconut oil

Coconut oil is a popular ingredient that’s often found in skincare and haircare products. It’s luxuriously rich and hydrating, so it’ll leave your skin feeling softened and refreshed. If you’d like to have a coconut fragrance in your soap, opt for virgin coconut oil.

If you want all of the benefits of coconut oil without the scent, choose refined coconut oil instead.

Olive oil

Olive oil has been used on the skin and hair for thousands of years. It contains skin-loving antioxidants and is packed with vitamin E.

You’ll see the best results if you use high-quality extra virgin olive oil in your soaps. It’s extracted from organic olives using low temperatures and no solvents.

This recipe features babassu oil, which is extracted from the kernels of the Brazilian babassu tree. This is a creamy oil, which doesn’t have a strong fragrance.

Babassu oil softens the skin and can be absorbed quickly, so it’s often recommended for people with skin conditions such as eczema and psoriasis.

Castor oil

Castor oil is a fabulous natural moisturiser, which makes it perfect for this soothing soap recipe. It has lots of fatty acids and is a common skincare ingredient as a result. It’s fantastic in hair products too!

It has a warm golden colour and a neutral fragrance, so it won’t overpower any essential oils that you choose to add.

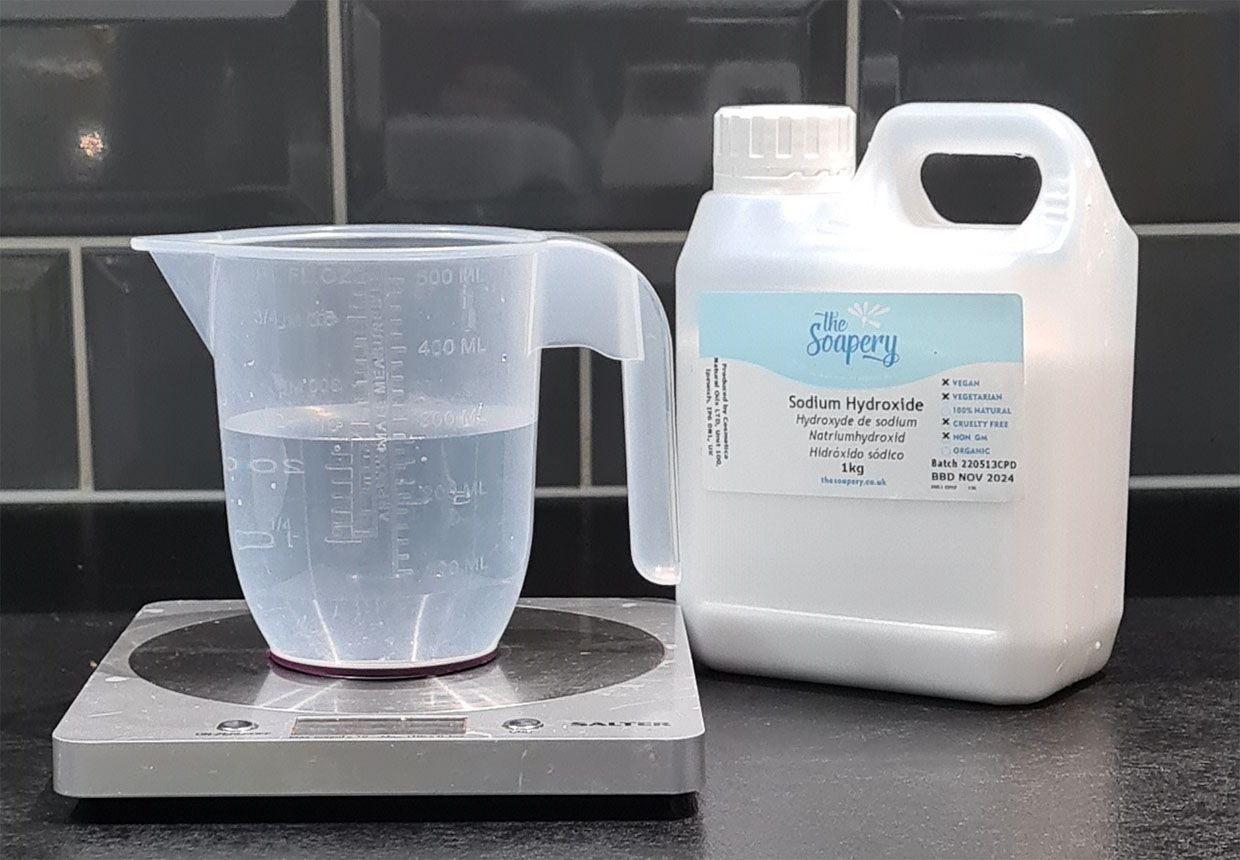

Sodium hydroxide (lye)

Sodium hydroxide is a crucial ingredient in cold process soap making, as it’s needed to kickstart the saponification process.

Sodium hydroxide is sometimes referred to as caustic soda or lye. It’s a white powder that’s highly alkaline.

Lye is highly toxic and needs to be handled with care. Don’t worry though there will be no lye left in your soap once the curing process has finished.

Essential oils

When you add essential oils to your soap you can transform it into something special and make it uniquely yours..

Lavender essential oil

Lavender oil is known for its comforting floral scent and relaxing properties, so it’s often used to calm the mind before sleep. It has a strong, sweet smell and a little goes a long way.

Although lavender oil is suitable for most skin types, be aware that some people report skin irritation when using it.

May chang essential oil

You may not have come across may chang essential oil before, but it’s worth getting acquainted with this fabulous natural ingredient.

May chang essential oil is distilled from the fruit of the Litsea Cubeba plant in China. It has a bright citrus scent with sweet and spicy undertones. The sweet smell is reminiscent of lemongrass and citronella.

You should consult a doctor before use if you are pregnant and don’t apply it directly to the skin.

Rosemary essential oil

A few drops of rosemary essential oil can add an uplifting note to your soap. It has a woody, herbal fragrance, which we love! This vibrant essential oil is 100% natural without any synthetic fragrances.

Do not consume rosemary essential oil and check with your doctor before using it if you are pregnant.

Cold process soap making equipment

Before you start making cold process soap, you’ll need a few important pieces of kit. Here’s what you’ll need:

- Gloves

- Goggles

- Weighing scales

- Hand blender

- A silicone soap mould or DIY alternative

- 3x plastic jugs. Ideally 1x 2L and 2x 1L

- Silicone spatula

- Digital thermometer

Important safety information

Sodium hydroxide is caustic, so make sure you wear gloves and goggles when you're handling it. You definitely don't want it to come into contact with your skin or eyes.

When you're mixing sodium hydroxide with water it will heat up to 80-90℃. Do this next to an open window, as the fumes are unpleasant.